Metal cutting is an essential part of many industries, from automotive to construction. Achieving precise cuts in steel can be challenging with traditional cutting methods. However, with modern technology, laser steel cutting machines have revolutionized the way metals are shaped and fabricated. These machines allow for accuracy, efficiency, and high-quality results that are difficult to achieve with conventional tools.

Understanding Laser Steel Cutting Machines

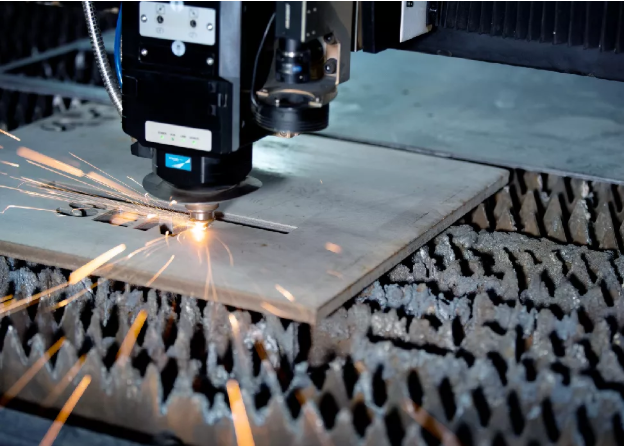

A laser steel cutting machine is a specialized tool that uses a focused beam of light to cut through steel and other metals. The laser heats the metal to a very high temperature, melting or vaporizing it along the cutting path. This method is highly controlled, allowing the machine to make detailed cuts that are smooth and precise. Unlike mechanical cutting tools, lasers do not apply physical force to the metal, reducing the risk of deformation.

The Precision Advantage

One of the main benefits of using a laser steel cutting machine is its ability to produce highly precise cuts. The focused laser beam can cut complex shapes and patterns with minimal error. This precision is especially important in industries that require exact dimensions, such as aerospace, automotive, and electronics. Because the cuts are clean and accurate, less material is wasted, which saves costs and improves overall efficiency.

Speed and Efficiency

Laser steel cutting machines are also known for their speed. They can cut through thick and thin sheets of steel much faster than traditional cutting methods. The automation involved in these machines allows for continuous operation with minimal human intervention. This efficiency reduces production time and increases output, making them ideal for high-volume manufacturing environments.

Versatility in Cutting

Another significant advantage of laser steel cutting machines is their versatility. They can cut a wide range of steel types, including stainless steel, carbon steel, and alloy steel. Additionally, they are capable of performing various cuts, such as straight lines, curves, and intricate patterns. This flexibility allows manufacturers to experiment with designs and create components that would be challenging to achieve using conventional methods.

Minimal Material Waste

Traditional cutting methods often produce rough edges and require additional finishing work. Laser steel cutting machines, on the other hand, provide clean edges that often do not require further processing. This reduces material waste and saves both time and money. The precision of the cuts ensures that more of the raw material is used efficiently, which is beneficial for large-scale production and environmentally conscious manufacturing.

Safety and Reduced Maintenance

Laser steel cutting machines also offer safety advantages. Since they do not rely on physical blades or high-pressure cutting, the risk of accidents is reduced. Additionally, these machines require less maintenance compared to mechanical cutting tools because there are no moving blades to wear out. This reduces downtime and ensures that production remains consistent.

Integration with Modern Technology

Many modern laser steel cutting machines are equipped with computer-controlled systems. These systems allow operators to program exact cutting patterns and adjust settings for different materials. Integration with software makes it easier to replicate designs and maintain uniformity across multiple pieces. This technological integration enhances precision and allows for innovative designs that were previously difficult or impossible to achieve.

Conclusion

Laser steel cutting machines have transformed metal fabrication by providing unmatched precision, speed, and versatility. They reduce material waste, lower maintenance needs, and improve safety in the workplace. By combining advanced technology with precise cutting capabilities, these machines help manufacturers achieve high-quality results consistently. Whether for complex designs or high-volume production, a laser steel cutting machine is an essential tool for achieving accurate and efficient metal cuts.